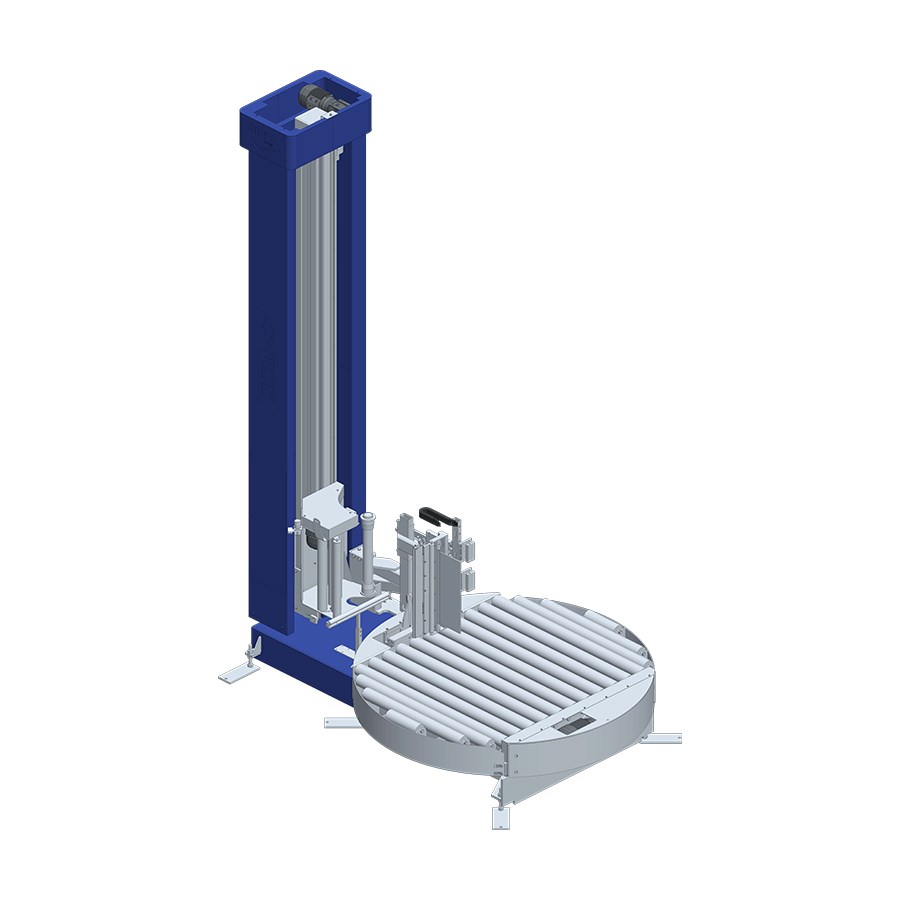

Improve pallet stability with a stretch wrapping machine

Improve pallet stability with a stretch wrapping machine

Blog Article

Release Performance in Your Stockroom Operations With a Premium Stretch Covering Maker

The introduction of a top quality stretch covering maker can be a game-changer, appealing efficiency, lowered labor prices, and reduced human error. With the capacity to handle numerous tons dimensions and cover various pallets per hour, these machines supply a compelling proposition for any kind of company looking to maximize its operations.

Understanding the Duty of Stretch Wrapping Machines in Stockroom Workflow

In the vast world of stockroom operations, the relevance of stretch wrapping machines can not be overemphasized. They offer a critical function in making certain that products are securely and securely packed for storage or transport. These devices apply a very stretchable plastic movie around products, tightly covering them with each other in a way that hands-on covering simply can not match.

Stretch wrapping equipments can manage big quantities of items swiftly, dramatically speeding up the packaging procedure. The consistent covering offered by these devices can minimize the danger of meddling or theft during transit.

Secret Features of High-Quality Stretch Covering Machines

While there is a vast variety of stretch covering devices readily available out there, top quality versions share specific key attributes that set them apart. These equipments are normally durable, designed to hold up against substantial use without jeopardizing on efficiency. They provide a high level of automation, enabling problem-free and reliable wrapping of items.

High-quality stretch covering equipments also include flexible settings, supplying adaptability to match various packaging requirements. They can take care of different sizes and sorts of lots, ensuring a safe cover each time. These makers are also renowned for their speed, capable of covering various pallets per hour, therefore substantially increasing efficiency.

An additional key feature is their reliability and low maintenance requirement. Premium devices are developed to last, decreasing the frequency of breakdowns and the associated downtime. They run with accuracy, guaranteeing consistent cover stress, consequently reducing waste and boosting the discussion of covered items.

The Impact of Stretch Wrapping Devices on Storehouse Effectiveness

The effectiveness of a storage facility can be considerably improved with making use of high-quality stretch covering devices - stretch wrapping machine. These machines simplify the packaging procedure, reducing the manual labor entailed and subsequently, the chance for human mistake. This makes sure a more consistent and trusted covering process, causing boosted security of items during transportation

Additionally, stretch covering devices can take care of a greater quantity of products in a much shorter amount of time contrasted to hands-on covering. This heightened Resources efficiency can cause better usage of warehouse area as items can be packaged and moved extra quickly. The makers also use the flexibility to fit various sizes and forms of goods, better boosting browse around this site operational effectiveness.

Computing the Roi for a Stretch Wrapping Machine

Considering the substantial benefits of stretch wrapping machines, it's crucial to recognize the monetary implications of purchasing such tools. The return on investment (ROI) calculation is a straightforward yet efficient tool to assess the productivity of this investment. The ROI is calculated by contrasting the cost of the machine with the financial savings produced over a specific duration.

The higher the ROI, the much more rewarding the financial investment. This number should not be the single component in the decision-making procedure. Businesses should also consider factors such as strategic alignment, operational performance, and scalability. Finally, computing the ROI gives a clear economic point of view to lead the financial investment choice in stretch covering makers.

Real-world Instance Research Studies: Success Stories of Executing Stretch Wrapping Machines

Drawing from the economic ramifications talked about in the previous area, it is similarly enlightening to check out functional applications and success stories of firms that have implemented stretch covering devices in their operations. One such instance is a multinational electronic devices company which reported a 30% decrease in damaged goods throughout transit after presenting stretch wrapping equipments in their packaging procedure.

One more success tale involves a leading food and drink business. After executing a stretch covering equipment, they witnessed a significant enhancement in their packaging speed, which subsequently enhanced daily results and general performance.

Lastly, a prominent furniture maker was able to lower their product packaging material costs by an incredible 40% after switching to stretch covering machines; they concurrently minimized their carbon footprint, making their operations extra sustainable. These real-world situation studies demonstrate the impressive returns and effectiveness gains that extend covering machines can give stockroom operations.

Verdict

Finally, investing in a why not try here premium stretch covering equipment can significantly improve storehouse procedures. With its capacity to reduce hands-on labor, lessen errors, and enhance space use, it substantially enhances productivity and success. The ROI, paired with success tales from real-world implementations, further underscores the essential role of stretch covering equipments in achieving operational effectiveness and organization success.

The intro of a premium stretch covering maker can be a game-changer, appealing effectiveness, decreased labor expenses, and reduced human error.In the vast world of warehouse procedures, the importance of stretch wrapping equipments can not be overemphasized.The efficiency of a warehouse can be considerably improved with the use of top quality stretch wrapping devices.Furthermore, stretch wrapping makers can take care of a greater quantity of products in a shorter quantity of time contrasted to manual covering.In final thought, investing in a high-quality stretch covering device can considerably boost storehouse operations.

Report this page